Construction Layout Tools: A Definitive Guide to Faster, More Accurate Stakeouts

In the world of construction, precision and efficiency are not just goals; they're necessities. That's where construction layout tools come into play, revolutionizing the way projects are brought to life. From the foundational stakeouts to the final touches, these tools ensure that every beam, pipe, and panel is exactly where it should be.

Imagine turning complex blueprints into reality with the push of a button or the glance through a lens. With gadgets like laser levels that cast unfaltering lines across uneven surfaces, and GNSS systems that pinpoint locations with startling accuracy, the construction industry is experiencing a surge in productivity and precision. This guide dives deep into the world of construction layout tools, exploring how they're making stakeouts faster, reducing material waste, and ensuring projects stay on track.

Whether you're a seasoned professional or new to the field, understanding these tools' capabilities and applications can transform the way you view construction projects. So, let's embark on this journey together, exploring the definitive guide to construction layout tools and how they're shaping the future of construction.

What Are Construction Layout Tools?

Construction layout tools are crucial for translating architectural and engineering designs into accurate, on-the-ground physical references at the construction site. Modern layout workflows emphasize precision, speed, and digital integration, making advanced instruments essential in today’s fast-paced building environments.

The most widely adopted tools in modern construction layout include robotic total stations, GNSS-based systems, digital levels, and construction layout tablets or data collectors.

- Robotic total stations like the Trimble S Series Total Stations, which combine the functions of theodolites with electronic distance measurement, are pivotal for detailed surveying and layout tasks.

- GNSS-based systems provide centimetre-level accuracy over large areas, making them ideal for road construction, utility alignment, and large infrastructure projects where control points are widely spaced.

- Digital levels offer unmatched accuracy for vertical alignment and elevation transfer, crucial in structural foundations and grading tasks.

- Construction layout tablets and data collectors streamline workflows by integrating CAD files, automated layout instructions, and field data capture into a single interface, reducing manual input and improving productivity.

Understanding the intent behind searching for construction layout tools reveals a need for accuracy, efficiency, and reliability in the construction process. These tools are interconnected in their purpose to minimize errors, reduce waste, and ensure that construction projects meet design specifications and regulatory standards.

Ensures Structural Integrity

Accurate stakeouts are crucial for maintaining the structural integrity of a building. They ensure every component is placed according to precise specifications, which is vital for the building's stability and safety.

Reduces Material Waste

Accurate stakeouts help minimize material waste by enabling precise placement. This saves resources, contributes to environmental sustainability, and reduces the overall project cost.

Saves Time and Costs

Efficiency in stakeouts translates to fewer errors and revisions, significantly saving time and reducing costs associated with construction projects. This efficiency ensures projects stay on schedule and within budget.

What Are The Types of Construction Layout Tools?

The construction industry utilizes a variety of layout tools, each designed to meet specific needs and enhance accuracy and efficiency in stakeouts. Together, they form a comprehensive arsenal for construction professionals, facilitating faster, more accurate stakeouts that underpin successful project completions. Let’s take a closer look at what they are and what functions they have which make construction easier:

GNSS Systems

GNSS systems enhance construction layouts with real-time positioning, crucial for managing large-scale projects efficiently. They integrate seamlessly with digital plans, providing a dynamic tool for precise stakeouts over extensive areas.

Total Stations

Total stations, such as the Trimble S Series Total Stations, are valued for their high precision measurements and versatility. They combine the functionalities of electronic distance measurement and angle calculation, making them indispensable for a variety of construction tasks.

Laser Levels

Laser levels facilitate quick horizontal and vertical alignment, essential for both indoor and outdoor construction activities. Their ease of use and accuracy speed up the layout process, ensuring structures are level and aligned.

Theodolites

Theodolites play a critical role in projects that require meticulous alignment, such as road and bridge construction. Their precision in measuring angles is unmatched, supporting complex layout tasks.

Digital Levels

Digital levels offer enhanced accuracy in elevation measurements. They are particularly useful in tasks that demand high levels of precision, streamlining the process of achieving accurate and reliable stakeouts.

One standout tool in this category is the Trimble DiNi, known for its high-precision elevation measurement capabilities and digital data collection, making it ideal for engineering-grade leveling tasks.

How Do GNSS Systems Enhance Construction Layout Accuracy?

GNSS systems significantly enhance construction layout accuracy through real-time positioning. This capability allows for the precise placement of structures on a site, ensuring that they align perfectly with digital plans. By integrating GNSS data with these plans, construction teams can execute stakeouts with a level of productivity previously unattainable.

This integration not only streamlines the layout process but also reduces the likelihood of errors that can arise from manual measurements and interpretations. Consequently, GNSS systems play a pivotal role in modern construction practices, facilitating faster, more accurate stakeouts that contribute to the overall efficiency and success of construction projects.

Real-time Positioning

Real-time positioning, provided by GNSS systems, ensures that every component of the construction project is placed with unparalleled productivity. This technology minimizes deviations on large projects, allowing for an exact replication of the digital blueprint on the physical site.

Integration with Digital Plans

Integration with digital plans enables construction teams to directly overlay GNSS data onto project schematics. This harmonization between digital plans and real-world coordinates significantly boosts layout accuracy, facilitating the flawless execution of construction projects.

What Are The Advantages Of Using Total Stations For Stakeouts?

Total stations offer significant advantages for construction stakeouts, primarily through high precision 3D measurements. This precision is crucial for ensuring that every aspect of the construction layout aligns with the project's specifications, thereby reducing the risk of costly errors.

Additionally, total stations provide versatility in data collection, capable of capturing both distance and angle measurements with ease. The versatility of equipment like the Trimble S Series Total Stations allows construction teams to use a single tool for a variety of layout tasks, streamlining the process and enhancing efficiency on the job site.

By combining accuracy with flexibility, total stations have become an indispensable tool in modern construction stakeouts, contributing to more accurate, efficient, and successful project completions.

High Precision 3D Measurements

High precision 3D measurements are a hallmark of total stations, enabling construction teams to measure both 2D and elevation with high accuracy. This precision ensures that all elements of a project align perfectly with planned specifications, minimizing the potential for error.

Versatility in Data Collection

Versatility in data collection allows total stations to adapt to various construction tasks, from distance measuring to angle calculation. This adaptability streamlines the stakeout process, making total stations a versatile tool in the construction industry.

How Do Laser Levels Contribute To Faster Construction Layouts?

Laser levels like the Spectra Precision LL300N contribute to faster construction layouts by providing quick horizontal and vertical alignment. This capability enables construction teams to ensure that structures are perfectly level and aligned with a fraction of the effort and time required by traditional methods.

Their suitability for both indoor and outdoor use expands their utility across various construction scenarios, from laying foundations to installing interior finishes. By simplifying and speeding up the alignment process, laser levels play a pivotal role in enhancing the efficiency and productivity of construction projects.

Quick Horizontal and Vertical Alignment

Quick horizontal and vertical alignment, facilitated by laser levels, ensures rapid and precise positioning of construction elements. This capability significantly accelerates the layout process, contributing to the overall efficiency and accuracy of construction projects.

Ideal for Indoor and Outdoor Use

Laser levels prove to be ideal for indoor and outdoor use, showcasing their versatility across a wide range of construction environments. Their adaptability makes them an invaluable tool for projects that span from foundational work to interior finishings, enhancing both efficiency and precision.

Why Are Total Stations Essential for Modern Surveying?

Total stations have become indispensable in modern surveying and construction layout due to their ability to combine precise angle measurement, electronic distance measurement (EDM), and digital data collection in a single, integrated instrument. These advanced tools offer higher efficiency, improved accuracy, and real-time capabilities that far surpass traditional instruments like theodolites.

Integrated Angle and Distance Measurement

Total stations precisely measure both horizontal and vertical angles while simultaneously calculating distances using EDM technology. This dual functionality streamlines workflows by eliminating the need for separate devices, enabling faster and more accurate layout and data collection.

Critical for Construction Layout and Infrastructure Projects

From building foundations to road and bridge alignments, total stations are vital for high-precision layout tasks. They allow surveyors and construction crews to stake out complex geometries, elevations, and reference points with accuracy down to millimetres, which is critical for structural integrity and compliance with engineering specifications.

Enhanced Productivity with Robotic Operation

Modern robotic total stations can be operated by a single person using a controller or data collector, significantly reducing labour requirements. Automated tracking and targeting systems enhance speed, reduce error, and support real-time data capture in the field.

Digital Data Integration and Documentation

Total stations support seamless integration with CAD files, BIM models, and field software. This enables surveyors to directly upload and extract data, perform real-time calculations, and generate reports, ensuring data consistency across the project lifecycle.

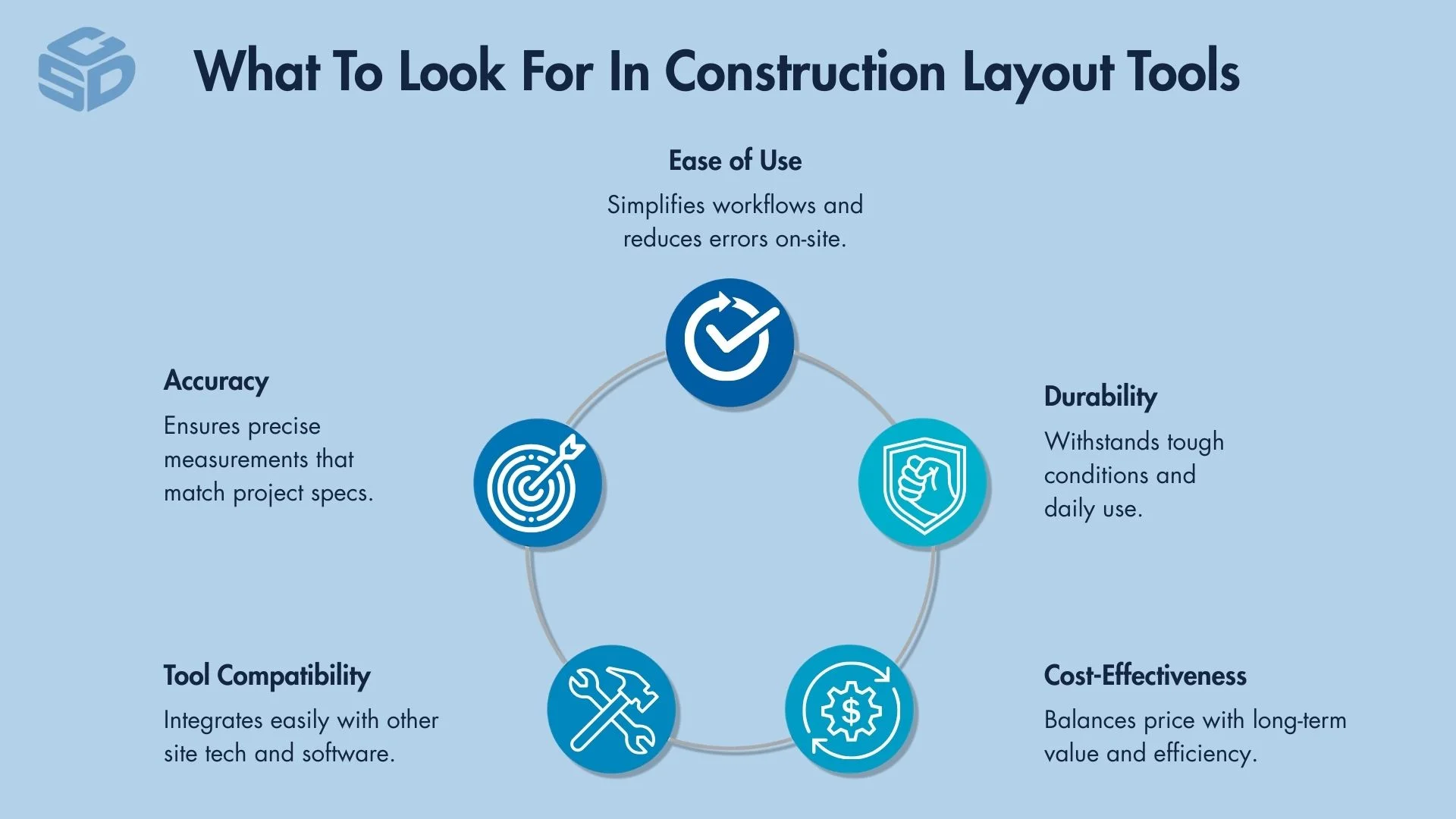

What Factors to Consider When Choosing Construction Layout Tools

When selecting construction layout tools, several factors are critical to ensure the success and efficiency of a project. Accuracy is paramount, as the precision of measurements directly impacts the structural integrity and functionality of the construction

Ease of use is also essential, as tools that are user-friendly can significantly enhance productivity and reduce the likelihood of errors. Durability is another important consideration, given the harsh conditions often encountered on construction sites; tools must withstand the elements and wear from regular use. Compatibility with other tools ensures seamless integration into existing workflows, maximizing efficiency.

Lastly, cost-effectiveness plays a vital role in the decision-making process, balancing the initial investment against the long-term benefits and savings from reduced errors and increased efficiency.

Together, these factors guide professionals in choosing the right tools that align with the specific demands and constraints of their construction projects.

Accuracy

Accuracy is paramount for construction layout tools, as precise measurements are essential to match project specifications, ensuring structural integrity and project success.

Ease of Use

Ease of use significantly impacts productivity, with user-friendly tools minimizing errors and streamlining the construction process for all involved.

Durability

Durability ensures that construction layout tools can withstand the rigours of harsh job site conditions and frequent use, offering reliability over time.

Compatibility with Other Tools

Compatibility with other tools is crucial for efficient workflow integration, allowing for seamless data exchange and enhancing overall project coordination.

Cost-effectiveness

Cost-effectiveness evaluates the balance between the tool's price and its performance, ensuring that investments in construction layout tools yield substantial returns through efficiency and accuracy.

How To Integrate Modern Layout Tools into Traditional Construction Processes

Integrating modern layout tools into traditional construction processes involves a strategic approach to training the workforce, updating project management approaches, and leveraging data for improved decision-making. Training is essential to familiarize the construction team with new technologies, ensuring they can utilize these tools effectively. Updating project management approaches means incorporating digital tools into the planning and execution phases, allowing for real-time adjustments and increased collaboration.

Leveraging data involves using the insights gathered from modern tools to make informed decisions, optimizing construction processes, and enhancing project outcomes. This integration not only streamlines construction activities but also significantly boosts accuracy, efficiency, and overall project success.

Training for Workforce

Training for the workforce is essential in equipping construction teams with the necessary skills to effectively utilize modern layout tools. This step ensures that all members can operate these technologies accurately, enhancing on-site efficiency.

Cansel offers a wide range of professional training options, from online learning to in-person instruction, designed to boost accuracy, efficiency, and confidence in the field.

- Can-Learn Online Platform: Flexible, self-paced training on tools like Trimble Access and TBC. Ideal for consistent, scalable team learning.

- Classroom & Custom Training: Small-group, instructor-led sessions tailored to your projects, workflows, and data.

- Onsite Training & Workflow Analysis: Cansel’s experts deliver hands-on training at your location, optimizing real-world project execution from data collection to delivery.

Updating Project Management Approaches

Updating project management approaches involves integrating digital tools and software into the construction workflow. This adaptation streamlines project planning, monitoring, and execution, leading to more efficient operations and minimized errors.

Leveraging Data for Improved Decision-Making

Leveraging data from modern layout tools supports informed decision-making. Utilizing this data can significantly optimize construction processes, improve project outcomes, and contribute to cost savings, making it a critical strategy for modern construction management.

Common Challenges In Using Construction Layout Tool

Common challenges in using construction layout tools include calibration issues, regular maintenance checks, and environmental constraints. Let’s take a look at these common issues and how they impact project progress.

Calibration Issues

Calibration issues can significantly affect the accuracy of layout tools. Ensuring regular calibration is essential for maintaining precision in measurements.

Regular Maintenance Checks

Conducting regular maintenance checks is crucial for identifying and addressing potential issues promptly, preventing tool failure during critical construction tasks. CSDS’s dedicated service department supports this need with factory-trained technicians, fast turnaround times, and a fully stocked parts inventory, ensuring minimal downtime and maximum field productivity.

With multiple service centers across California and authorized repair capabilities for top brands like Trimble, their expert team keeps your equipment performing at its best and can assist with professional-grade maintenance and repairs. For added value, CSDS offers rental discounts during non-warranty repairs, and seasonal promotions to help reduce costs while your gear is in the shop.

Professional Calibration Services

Utilizing professional calibration services ensures that tools adhere to industry standards for accuracy, thereby enhancing the reliability of construction layouts.

Environmental Constraints

Environmental constraints can challenge the functionality and effectiveness of layout tools. Choosing rugged tools specifically designed for varying conditions can help mitigate these issues.

Weather-Resistant Equipment

Investing in weather-resistant equipment guarantees that construction layout tools perform optimally, regardless of environmental conditions. For example, the Spectra Precision LL300S Laser Level with HL760 Laser Receiver has an IP66 environmental rating and maintains performance even in rainy or dusty conditions, making it suitable for harsher environments.

Adapting Schedules to Weather Conditions

Adapting schedules to weather conditions is a strategic approach to minimize the impact of environmental factors on the use and efficiency of layout tools.

Training and Skill Requirements

Addressing training and skill requirements ensures that construction teams are well-equipped to utilize advanced layout tools effectively, enhancing operational proficiency.

On-Site Training Sessions

On-site training sessions offer hands-on experience, significantly improving the skill set of construction teams in the efficient use of layout tools. For example, CSDS’s field-based training programs go beyond tool operation, delivering practical instruction directly at your job site. Their experienced professionals provide project-specific guidance, from data collection to final deliverables.

Solid on-site training like Cansel’s ensures teams adopt best practices, optimize workflows, and maximize equipment performance in real-world conditions. These sessions are ideal when paired with classroom or custom training to give crews a complete understanding of the systems they’re using and how they apply across planning, layout, and construction stages.

Access to Online Tutorials and Manuals

Ensuring access to online tutorials and manuals facilitates continuous learning and effective problem-solving, keeping teams adept in the use and maintenance of construction layout tools.

One major resource for online tutorials and manuals is CSDS’s Can-Learn, where users gain access to a growing library of over 20+ online training courses, 200+ support documents and videos, and 50+ on-demand webinars, all focused on Trimble software like Trimble Business Center and Trimble Access. It’s designed for flexibility, allowing team members to learn at their own pace and on their own schedule, making it easy to stay sharp, adapt to software updates, and master advanced workflows without disrupting the jobsite.

Whether you're new to a platform or looking to refine your skills, giving fast and convenient access to learning materials keeps your team up to speed with insider tips, expert guidance, and regularly updated technical content.

Future Trends in Construction Layout Technology

The future of construction layout technology is poised for transformative advancements, with Augmented Reality (AR), autonomous drones, and the Internet of Things (IoT) leading the charge.

AR is set to revolutionize project visualization, allowing stakeholders to see the end result in real-time, superimposed on the existing environment. This technology promises to enhance accuracy and streamline the decision-making process.

Autonomous drones are becoming increasingly valuable for their ability to conduct site surveys quickly and accurately, gathering data from areas that are difficult or dangerous for humans to access. Lastly, the IoT's role in tool tracking and management is expected to significantly boost efficiency and reduce the likelihood of delays caused by misplaced or malfunctioning equipment.

Together, these trends signify a shift towards more integrated, efficient, and precise construction processes, heralding a new era of innovation in the construction industry.

Augmented Reality (AR) for Visualizing Projects

Augmented Reality (AR) is poised to revolutionize project visualization, enabling stakeholders to overlay digital designs onto the real-world environment. This technology enhances precision and streamlines decision-making by providing a real-time, immersive view of the intended outcome.

Trimble SiteVision is a leading AR solution that brings spatial data to life on mobile devices, allowing users to visualize design intent, inspect progress, and make quick measurements including points, lines, and cut/fill values directly on site.

Paired with the Trimble DA2, SiteVision delivers centimetre-level accuracy for confident, in-field decisions. The DA2 transforms your phone or tablet into a high-performance tool, making AR-based layout and issue tracking more accessible and precise.

By integrating SiteVision into the workflow, teams can collaborate more effectively, reduce rework, and fully understand how designs interact with the existing site environment in real time.

Autonomous Drones for Site Surveying

Autonomous drones are transforming the landscape of site surveying, offering a swift and precise method for gathering essential data from difficult-to-access or hazardous areas. Deploying drones like the DJI Mavic 3 E Enterprise increases safety and operational efficiency, marking a significant leap forward in construction technology.

Internet of Things (IoT) for Tool Tracking and Management

The Internet of Things (IoT) is reshaping tool tracking and management, giving construction professionals the ability to monitor valuable equipment in real time. By reducing downtime, minimizing loss, and improving maintenance workflows, IoT is setting a new standard for operational efficiency on the job site.

For example, Trimble Sentinel is an IoT-powered tracking solution designed for S-series total stations. It delivers real-time location tracking, impact alerts, and geofence notifications, so you always know where your instruments are and how they’re being handled.

Through its mobile app, teams can monitor instrument locations in real time, receive instant alerts when equipment is dropped or moved outside designated zones, and access usage data and equipment health. Sentinel also fits seamlessly into a larger digital ecosystem with Trimble Connect, where shared data and streamlined communication between field and office help drive faster decisions and better project outcomes.

With IoT-enabled tracking and integration-ready workflows, teams work smarter, protect their investments, and stay connected where it counts.